Stainless steel perforated mesh

Let Our Industry Experts Create Your Tailored Solution! Contact US !

Products Category

Tag list

- Description

-

Parameter

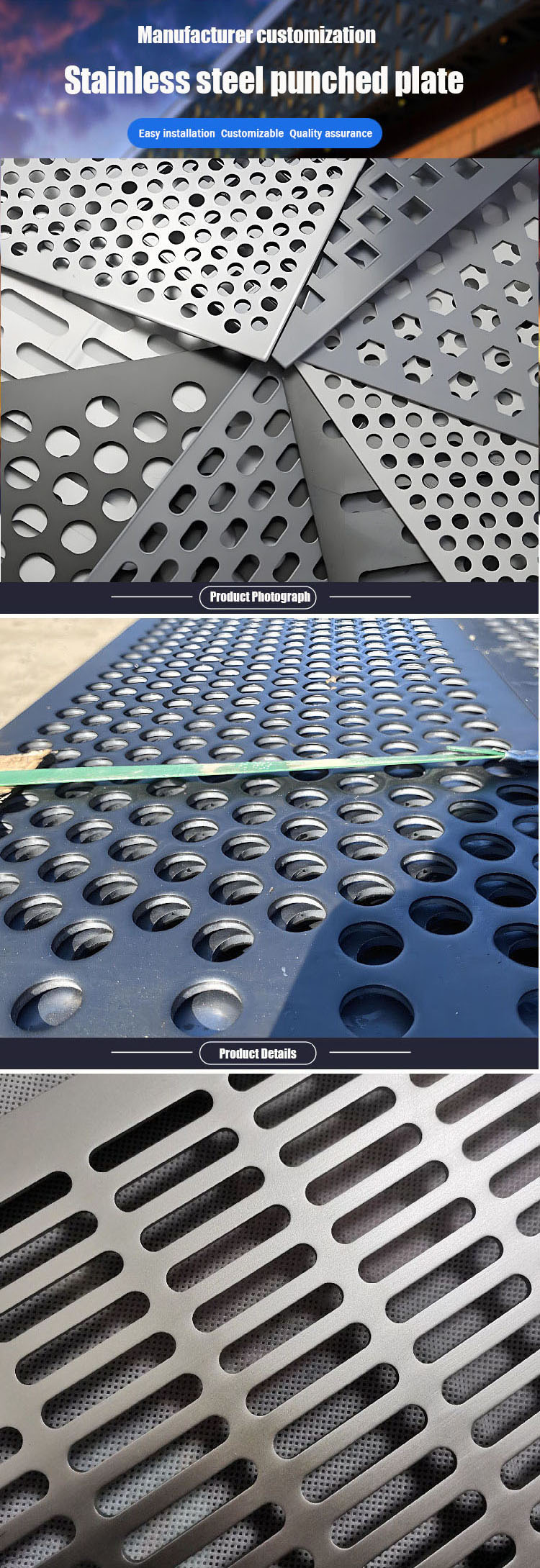

6mm Small Round Hole Stainless Steel Perforated 430 304ss Metal Mesh Sheet

6mm Decorative Stainless Steel Micron Metal Mesh Perforated Sheets

Punched Plate Screen Perforated Metal Sheet Wire Mesh Stainless Steel Round Hole Mesh Punching Sieve Plate

Stainless Steel Perforated Metal Sheet 316 Aluminum Perforated Metal Mesh Speaker Grille Sheet

Galvanized Perforated Metal Mesh Stainless Steel Perforated Sheet Hole Punching Sheets Construction Screen

We support personalized customization. From the shape of the mesh holes, the size specifications to the material selection and surface treatment, we can create exclusive solutions according to your requirements. Moreover, we have an efficient production process to ensure a rapid response after you place an order and guarantee quick delivery.

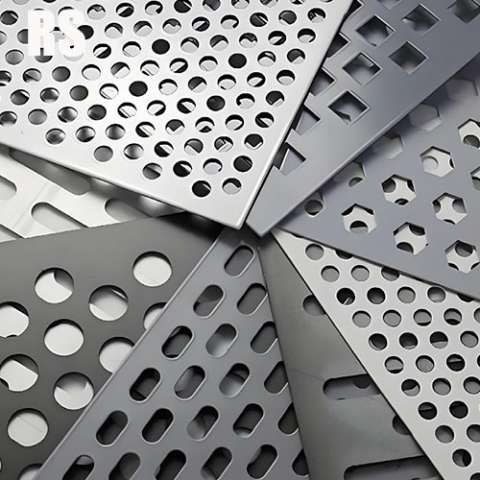

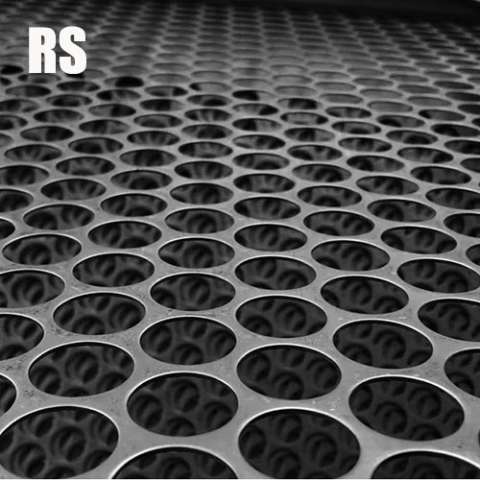

Stainless steel perforated mesh is a kind of metal mesh made by punching stainless steel plates with a certain hole pattern and mold on a CNC punching machine.

Material: Stainless steel plate.

Hole patterns: Long holes, round holes, square holes, triangular holes, fish scale holes, bridge holes, diamond holes, pentagonal holes, hexagonal holes, figure-eight holes, cross holes, nail-shaped holes, plum blossom holes, herringbone holes, I-shaped holes and other special-shaped holes.

Features: Light in weight, anti-slip, beautiful and generous, with good filtering performance.

Common materials of stainless steel perforated mesh plates: 201, 304, 321, 316 and 316L. (Among them, 304 stainless steel perforated mesh and 316 stainless steel perforated mesh are the most common types of stainless steel perforated mesh.)

Unique advantages of stainless steel perforated mesh:

1. It is non-flammable, odorless and non-toxic.

2. It has good wear resistance and a long service life. The wear resistance of stainless steel perforated mesh is 3 to 5 times that of ordinary screen plates and more than 5 times that of ordinary rubber screen plates.

3. The total cost is low. Although the one-time investment of a stainless steel perforated plate of a certain specification (area) is higher than that of an ordinary screen plate (about twice), due to the fact that the service life of the stainless steel perforated mesh is 3 to 5 times that of an ordinary screen plate, and the number of repairs and replacements is small, the total cost is not high and it is also cost-effective economically.

4. It has good vibration absorption performance and strong noise elimination ability, which can reduce noise and prevent the materials on the screen from being easily broken during the vibration process.

5. The stainless steel perforated mesh has good moisture resistance and can work under the condition with water as the medium.

6. The maintenance workload is small. The stainless steel perforated mesh is not easy to be damaged and has a long service life, so it can greatly reduce the maintenance volume and the losses caused by production suspension for maintenance. These unique advantages make stainless steel perforated mesh widely used in various industries.

Details show

QUALITY ASSURANCE

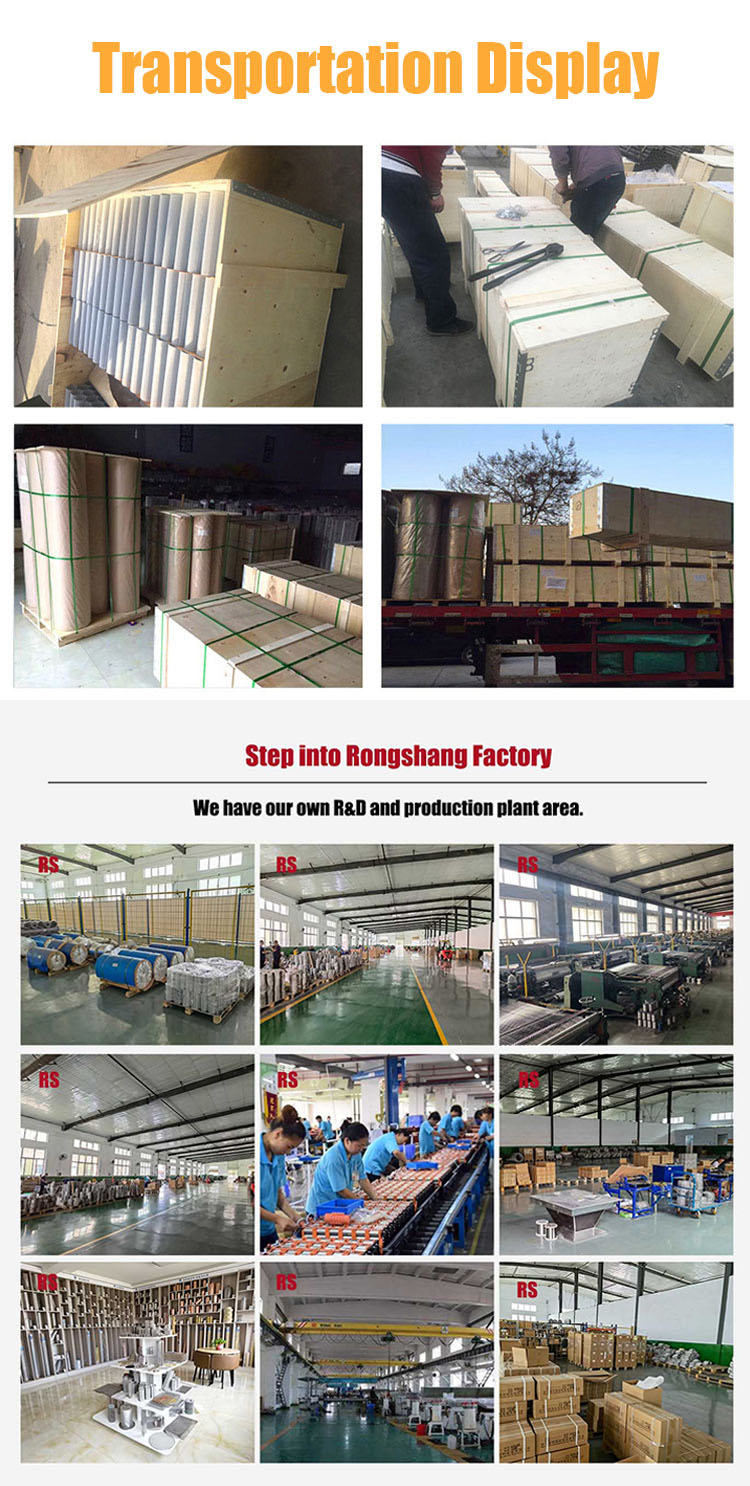

OWN FACTORY

CUSTOMIZED ON DEMAND

STRICT USE OF MATERIALS

FAST SHIPPING

INVOICING IS AVAILABLE

INTIMATE SERVICE

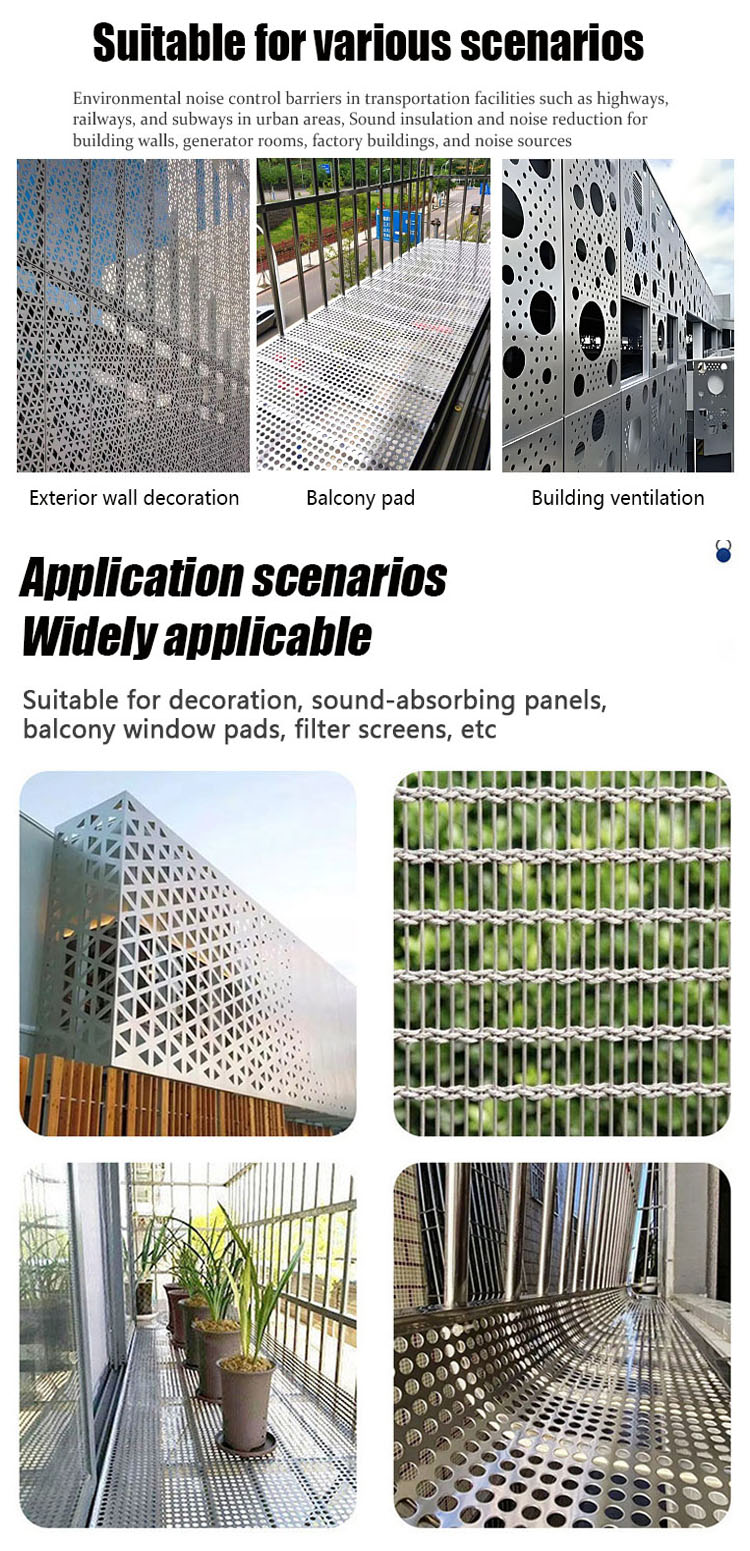

APPLICATION INDUSTRY

PRODUCTION SCENARIO

PRODUCTION SCENARIO

FAQ

Your company customize different mesh production?

Yes. we can by your drawing or sample or demand help u customize it.

What is the minimum order quantity (MOQ)? Can samples be provided?

Actually there is no MOQ for our products. But usually we recommend a quantity based on the price which is easy to accept.

Samples are free of charge, and only the shipping fee is charged.

How to get a quotation?

When you submit your requirements (material, specifications, quantity), we will send a detailed quotation within 1 hour. Discounts can be provided according to the order quantity - the larger the quantity, the better the price.

Does it support customized sizes, shapes, or special welding processes?

Yes, we provide non-standard customization services, including cutting, stamping, edge processing, etc., with the fastest delivery within 7 working days.

How do parameters such as mesh count, wire diameter, and aperture size affect product performance?

Mesh count (number of openings per inch) determines the filtration precision; wire diameter affects the strength and durability; the aperture size is inversely proportional to the mesh count. Please provide specific requirements (such as filter particle size or load-bearing requirements), and we will recommend matching specifications for you.

What are the differences in materials of stainless steel wire meshes (such as 304 and 316)? How to choose?

304 stainless steel has excellent corrosion resistance and is suitable for ordinary industrial or daily environments; 316 stainless steel adds molybdenum element, which provides stronger corrosion resistance and is suitable for corrosive environments such as chemical industry and coastal areas. We will recommend appropriate materials according to your usage scenarios.

Stainless steel perforated mesh

Let Our Industry Experts Create Your Tailored Solution! Contact US !

Products Category

Tag list

Request a Quote

We will contact you within one working day. Please pay attention to your email.

To: Anping Rongshang Wire Mesh Products Co., Ltd.

Related Products